Applying Computer Vision to X-ray Movies

Researchers have utilized machine learning, specifically “computer vision”, to analyze X-ray movies of rechargeable lithium-ion battery electrodes[^1^]. By examining each pixel in these movies, the researchers aim to uncover physical and chemical details that were previously unseen, potentially improving the efficiency of charge storage and release.

Battery Particle Composition and Operation

The battery particles examined in this research are made of lithium iron phosphate (LFP)[^1^], a material known for its low cost, good safety record, and use of abundant elements. LFP particles are coated with a thin layer of carbon to improve the electrical conductivity of the electrode and are packed into the positive electrodes of many lithium-ion batteries.

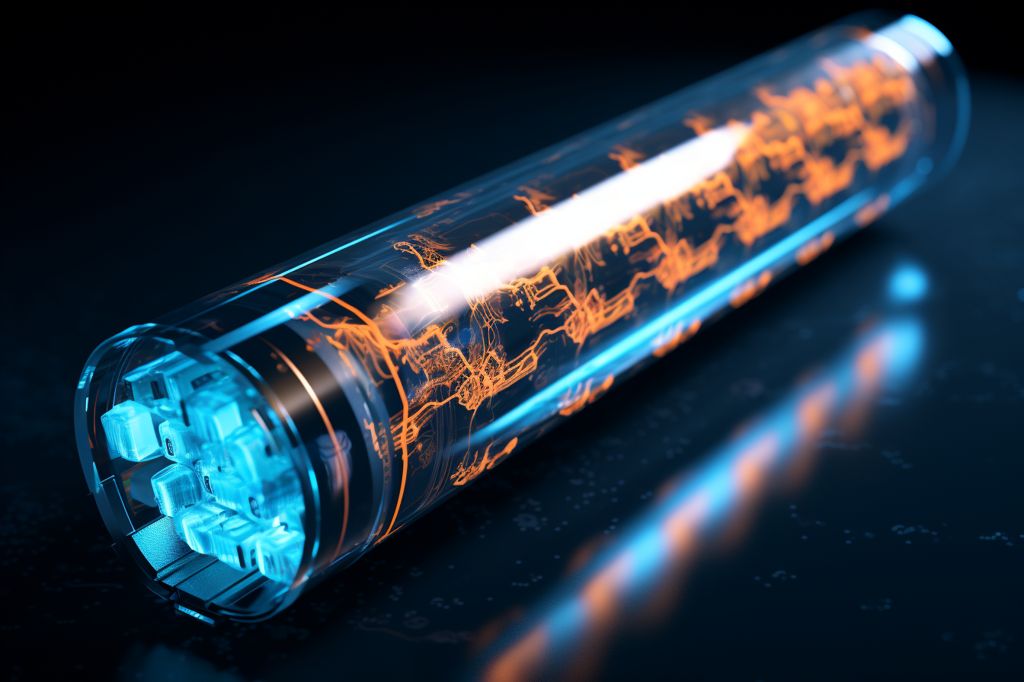

Tiny, transparent cell batteries were constructed to observe the battery’s functionality during operation. When discharging, lithium ions flow into the positive LFP electrode and lodge inside its nanoparticles through a process called intercalation[^1^]. During charging, the ions flow back out and travel to the negative electrode.

Machine Learning Techniques in Battery Research

The researchers have previously published groundbreaking nanoscale movies of lithium ions flowing in and out of individual LFP nanoparticles[^1^]. They then began using machine learning tools to accelerate battery testing and identify optimal charging methods. Additionally, they combined conventional machine learning with knowledge gained from experiments and physics-guided equations to discover and explain processes that shorten the lifetimes of fast-charging lithium-ion batteries.

In the current study, the research team used a subfield of machine learning called computer vision to mine more detailed information from 62 nanoscale X-ray movies of LFP particles charging or discharging, generating around 180,000 pixels of information[^1^].

New Findings and Potential Applications

With the help of computer vision, the researchers’ computational model produced equations that accurately described how lithium insertion reactions proceed. They discovered that the movements of the lithium ions within the LFP particles closely matched the predictions of their computer simulations[^1^].

This new technique has revealed several previously unseen phenomena, including variations in lithium ion insertion reaction rates in different regions of a single LFP nanoparticle[^1^]. Some regions appear to be faster while others seem to be slower.

Focus on the Interface

The most significant practical finding of the study is that variations in the thickness of an LFP particle’s carbon coating directly control the rate at which lithium ions flow in and out[^1^]. This discovery could potentially lead to more efficient charging and discharging of batteries.

The researchers suggest that the focus should be on engineering the interface between the liquid electrolyte and the solid electrode materials, where the intercalation reaction and variations in the thickness of the particles’ carbon coating interact in complex ways, essentially controlling battery processes[^1^].

[^1^]: Zhao, H., Deng, H.D., Cohen, A.E. et al. (2023) Learning heterogeneous reaction kinetics from X-ray videos pixel by pixel. Nature doi: 10.1038/s41586-023-06393-x